Industrial dust collector - air filter - pulse bag filter - dry mortar factory dust collector

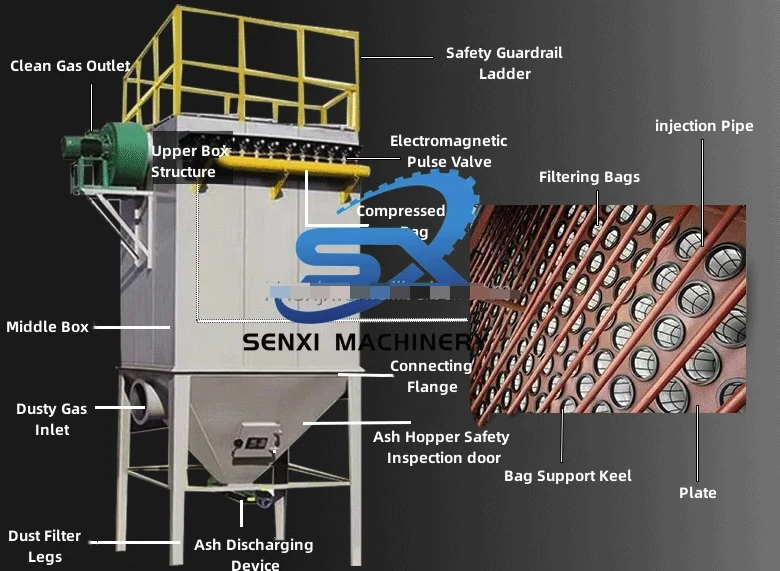

MC type pulse spray stand-alone bag filter is a bag filter designed after absorbing the advanced technology of foreign congeneric products. The modified pulse bag filter adopts high-pressure (0.5-0 Mpa) large-flow pulse valve bag-by-bag spray cleaning technology. Compared with other domestic stand-alone machines, it has the characteristics of large kinetic energy and high efficiency for cleaning. And it is small in size, light in weight, simple and compact in structure, easy to install and easy to maintain (external filter type). It is widely used in building materials, metallurgy, mining, chemical industry, coal, non-metallic ore ultra-fine powder processing and other industries. It is an ideal equipment for environmental protection dust removal.

Model | Filtering Area (m2) | Air Volume (m3/h) | Filtering Airspeed (m/min) | Working Resistance (Pa) | Dust Removing Pressure (Mpa) |

DMC-32 | 30 | 2880-4800 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-48 | 48 | 4320-7200 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-60 | 60 | 5400-9000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-72 | 72 | 6480-10800 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-90 | 90 | 8100-13500 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-120 | 120 | 10800-18000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-150 | 150 | 13000-22500 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-180 | 180 | 16200-27000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-210 | 210 | 18900-31500 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-250 | 250 | 22500-37500 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-270 | 270 | 24300-40500 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-300 | 300 | 27000-45000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-340 | 340 | 30400-51000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-420 | 420 | 37800-63000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-500 | 500 | 45000-75000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-600 | 600 | 54000-90000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-740 | 740 | 66600-111000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-870 | 870 | 78300-130500 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-1000 | 1000 | 90000-150000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

DMC-1100 | 1100 | 99000-165000 | 1.5-2.5 | 800-1800 | 0.4-0.6 |

After the dusty gas enters the Pulse jet dust collector from the upper box, it flows from top to bottom. After being filtered by a cloth bag, the dust is carried outside the bag, and the purified air is collected by the purification header at the bottom of the cloth bag and discharged from the outlet. When the dust on the surface of the cloth bag increases and reaches resistance, the control has issued instructions to sequentially trigger various electromagnetic valves, open pulse valves, and cause compressed air in the air bag to spray out a primary airflow at a speed close to the sound speed from each nozzle of the blowing pipe, thereby inducing a secondary airflow several times that of the airflow to spray into the filter bag together, causing the filter bag to instantly expand rapidly, causing the dust attached to the filter bag to detach from the cloth bag, Falling into the ash hopper through the gap between the clean gas header and then discharged by the ash discharge valve.

Get Free Quote

Fill in your request information

Product configuration