Working Principle of Dry Mix Mortar Plant

The working principle of a dry mix mortar plant involves a series of processes that result in the production of high-quality dry mortar products. Here are the key steps and the underlying principles of operation:

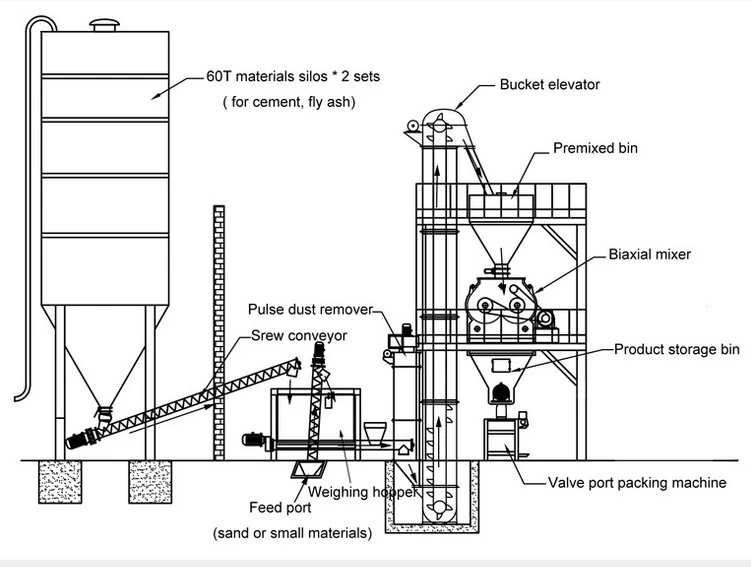

1. Raw Material Storage and Conveyance:

- Principle: The plant starts by storing raw materials such as cement, sand, additives, and other components in designated storage areas.

- Operation: Conveyor systems are used to transport the raw materials from storage to the mixing unit.

2. Weighing and Batching:

- Principle: Precise weighing of raw materials is crucial to ensure the correct proportions and quality of the dry mix mortar.

- Operation: Weighing systems measure and batch the required amounts of each raw material according to the pre-determined formulation.

3. Mixing:

- Principle: Thorough mixing is essential for achieving a homogenous blend of all components in the dry mortar.

- Operation: The pre-weighed materials are introduced into a mixing unit (dry mortar mixer) where they are blended evenly. The mixing process ensures uniform distribution of all ingredients.

4. Packaging:

- Principle: The mixed dry mortar is then packaged into bags or other containers for distribution and use.

- Operation: Automated packaging systems weigh the dry mortar and fill bags, ensuring accurate and consistent packaging.

5. Quality Control:

- Principle: Continuous quality control is implemented to monitor the consistency and adherence to specifications of the produced dry mortar.

- Operation: In-line testing and inspections are conducted at various stages of the process to ensure that the final product meets quality standards.

6. Storage and Distribution:

- Principle: Packaged dry mortar is stored in controlled environments to preserve its properties.

- Operation: Distribution networks transport the packaged dry mortar to construction sites or retail outlets as needed.

7. Dust Collection and Environmental Measures:

- Principle: Dust collection systems are employed to minimize environmental impact and create a safe working environment.

- Operation: Effective dust collection systems capture airborne particles generated during the production process.

8. Automation and Control:

- Principle: Advanced automation and control systems are utilized to optimize the efficiency and consistency of the production process.

- Operation: Control systems manage the entire plant operation, including material conveyance, weighing, mixing, and packaging, ensuring a streamlined and automated workflow.

9. Maintenance and Optimization:

- Principle: Regular maintenance is crucial for optimal plant performance and longevity.

- Operation: Scheduled maintenance tasks are carried out to address equipment wear and tear, ensuring reliable and efficient operation.

By following these principles and integrating advanced technology and automation, a dry mix mortar plant can consistently produce high-quality dry mortar products for various construction applications.