Tower type dry mixing mortar mixing plant

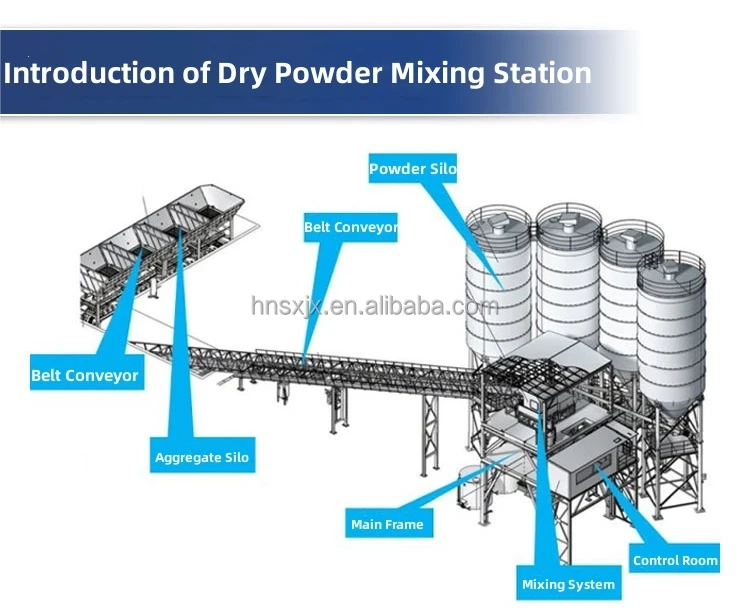

The tower type dry mix mortar mixing equipment is arranged from top to bottom according to the production process; the energy consumption is relatively low; the structure is compact, the floor area is small; the cross pollution of raw materials is small; the appearance is atmospheric, the equipment is magnificent, and it is suitable for the production of ordinary mortar and some special mortar. There are many production varieties, the efficiency is very high, the capacity can reach 200t/h, the operating cost is low, the output is large, and the investment is large. A production line layout mode in which the metering and batching system, mixing system, packaging and direct bulk system are arranged in a main production tower from top to bottom, and various materials are first directly lifted to the top of the tower, entered into their respective batching warehouses, and then carried out from top to bottom for subsequent production.

The Dry mortar powder plant is mainly composed of a dual axis weightless mixer, powder storage tank, screw conveyor, bucket elevator, powder measuring device (scale) for mixing, packaging machine, pulse dust collector, material level control system, alarm system, air compression system, and overall control system. Additionally, crushing and drying systems can be added as needed. The fully automatic dry powder mortar equipment is mainly used for the production of various dry powder mortars such as masonry mortar, plastering mortar, mortar required for insulation systems, decorative mortar, etc.

The main control system of this equipment issues production instructions based on the selected process formula, and the system automatically extracts raw materials according to the ratio from the storage bin. After the raw materials are weighed, they enter the waiting bin and the weightless high-efficiency mixer in order to achieve rapid mixing operation (3-5 minutes). After meeting the mixing accuracy requirements, the finished mortar is transported to the finished product bin with secondary mixing function and enters the automatic filling process, The newly designed automatic packaging machine performs quantitative filling operations according to requirements, greatly improving output efficiency. The packaged finished products are sent to the finished product area for stacking and waiting for delivery.

Get Free Quote

Fill in your request information

Product configuration